Expertise

Magnetron sputtering

Magnetron sputtering is a relatively mature technology, from small scale laboratory test stands to (very) large area industrial coating systems. There are several types of magnetron sputtering: DC, RF, pulsed DC, HiPIMS, including reactive sputtering, use of bipolar pulses, etc.

Deposition of thin films and (thick) coatings

Deposition processes should be selected and optimized depending on the material and applications. Thin films and coatings are used everywhere. The image shows a particular challenge: a high emissivity coating on a component used in an electron synchrotron.

Plasma sources

Plasma Engineering engages in solving challenges associated with plasma and ion beam processing of surfaces and materials such as HiPIMS and arc plasma deposition.

Cathodic arc sources for thin film deposition

Cathodic arcs deliver fully ionized plasma, most often with multiply charged ions. In the presence of a reactive gas, they are widely used to deposit hard, corrosion-resistant, low-friction and/or decorative coatings.

Plasma Diagnostics

There are many techniques to characterize plasma, among them optical techniques (non-disturbing), as well as probe and particle analysis methods. In most cases, it is highly desirable to use fast, space and time-resolving techniques.

Ion beam sources and their application: deposition and etching

Ion beam sources, especially broad beam ion sources, are used in applications such as ion beam sputter deposition of thin films and etching of surfaces for pattering and smoothing.

Plasma transport and filtering

Plasma transport from a generation region to a substrate is important for a system's efficiency. In some case one uses the transport path to filter the plasma, e.g. to remove particulates.

Diamond-like Carbon (DLC and ta-C)

Among the thin film materials, diamond-like carbon (DLC) plays a special role due to its properties. In the hydrogen-free version, the material is also known as tetrahedral amorphous carbon (ta-C). For the deposition one utilizes bias techniques to give ions 100 eV or more energy for subplanation growth.

Electric propulsion

Fast plasma flows and (space charge compensated) ion beams can be used for electric propulsion. Applications include satellite attitude control and propulsion for interplanetary and deep space missions.

Dielectric barrier discharges

Dielectric barrier discharges, which may be operated from low to atmospheric pressure, can be used, for example, to convert gas chemistries or deposit films by precursor decomposition.

Electrochromics and Thermochromics

Phase changes of (transparent) materials can be induced by intercalation of small ions (think hydrogen, lithium,...). Applications include, but are not limited to, energy-efficient windows.

Ion implantation and Plasma Immersion Ion Implantation

When ions are accelerated to keV - MeV energies, they can implanted below the surface. Ion acceleration can be accomplished in a dedicated ion sources and accelerators, or in a high voltage sheath using suitable bias power supplies. Of recent interest is the low-energy range, leading to "subplantation".

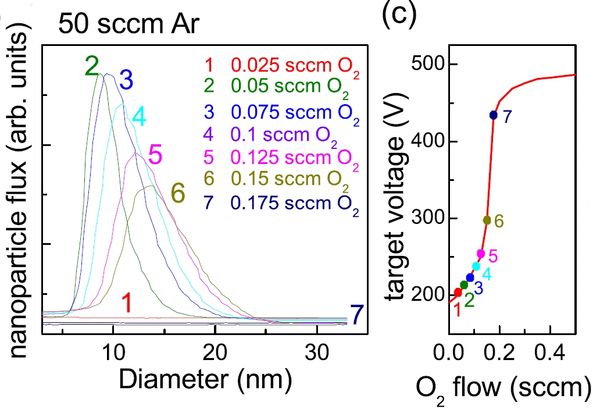

Nanoparticle generation by gas phase condensation

Clusters and nanoparticles can be produced by aggregation of material when atoms collide. For example, using a magnetron sputter source at high pressure, preferably with reactive gas, nanoparticles of the desired chemical composition and size can be obtained.

This website uses cookies.

We use cookies to analyze website traffic and optimize your website experience. By accepting our use of cookies, your data will be aggregated with all other user data.